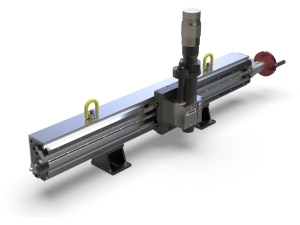

Mirage Portable Milling Machines

Mirage single axis, 2 axis portable milling machines from Enerpac are versatile machining tools that deliver workshop tolerances on-site. They remain true to the tried and tested technology and heritage of the Mirage Machines range of portable machine tools. The LMR range of portable mills are purpose-designed for machining heat exchanger division slots, but can also be used for “light” milling applications.

All Products

Viewing 1-1 of 1

Viewing 1-1 of 1