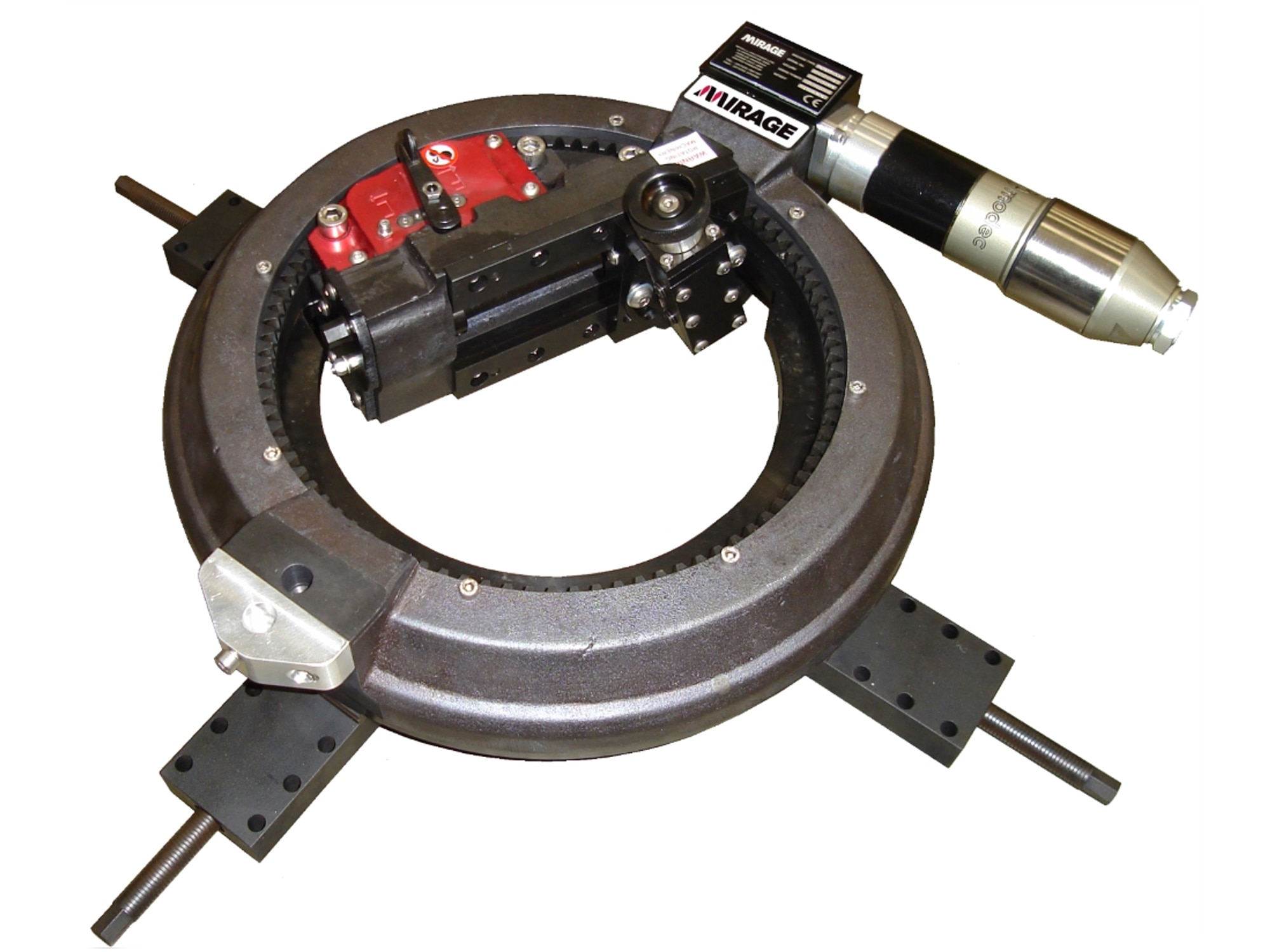

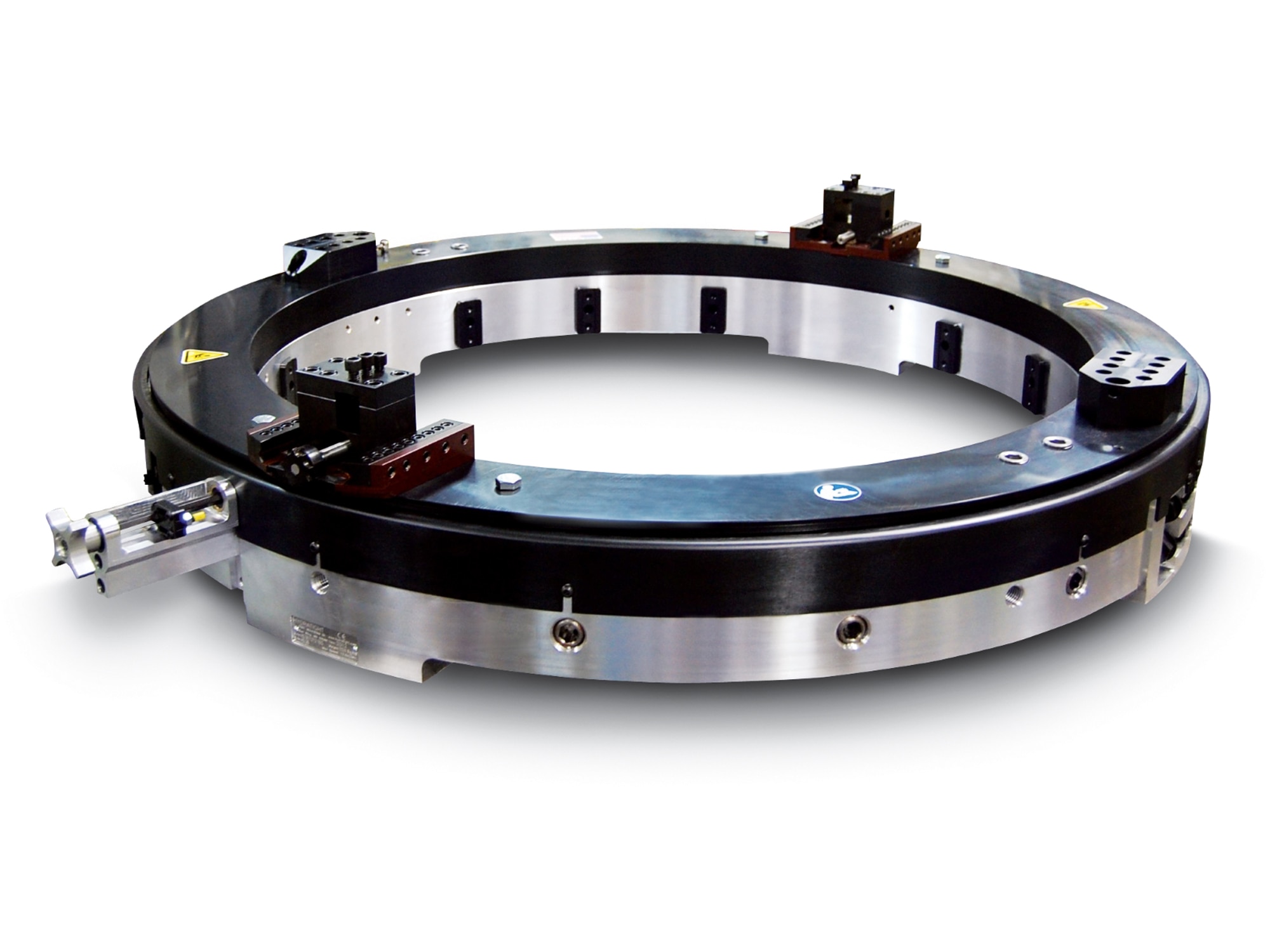

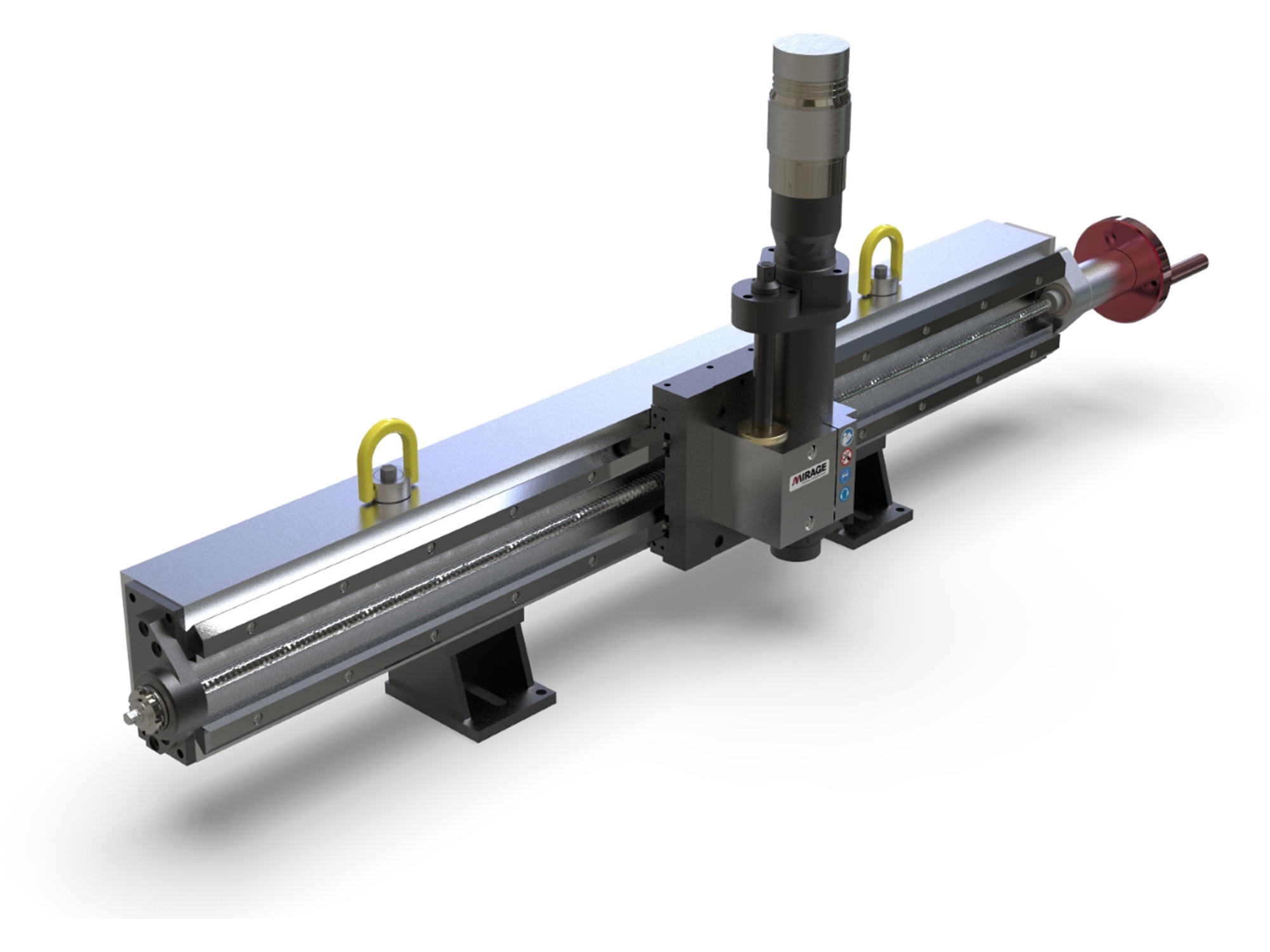

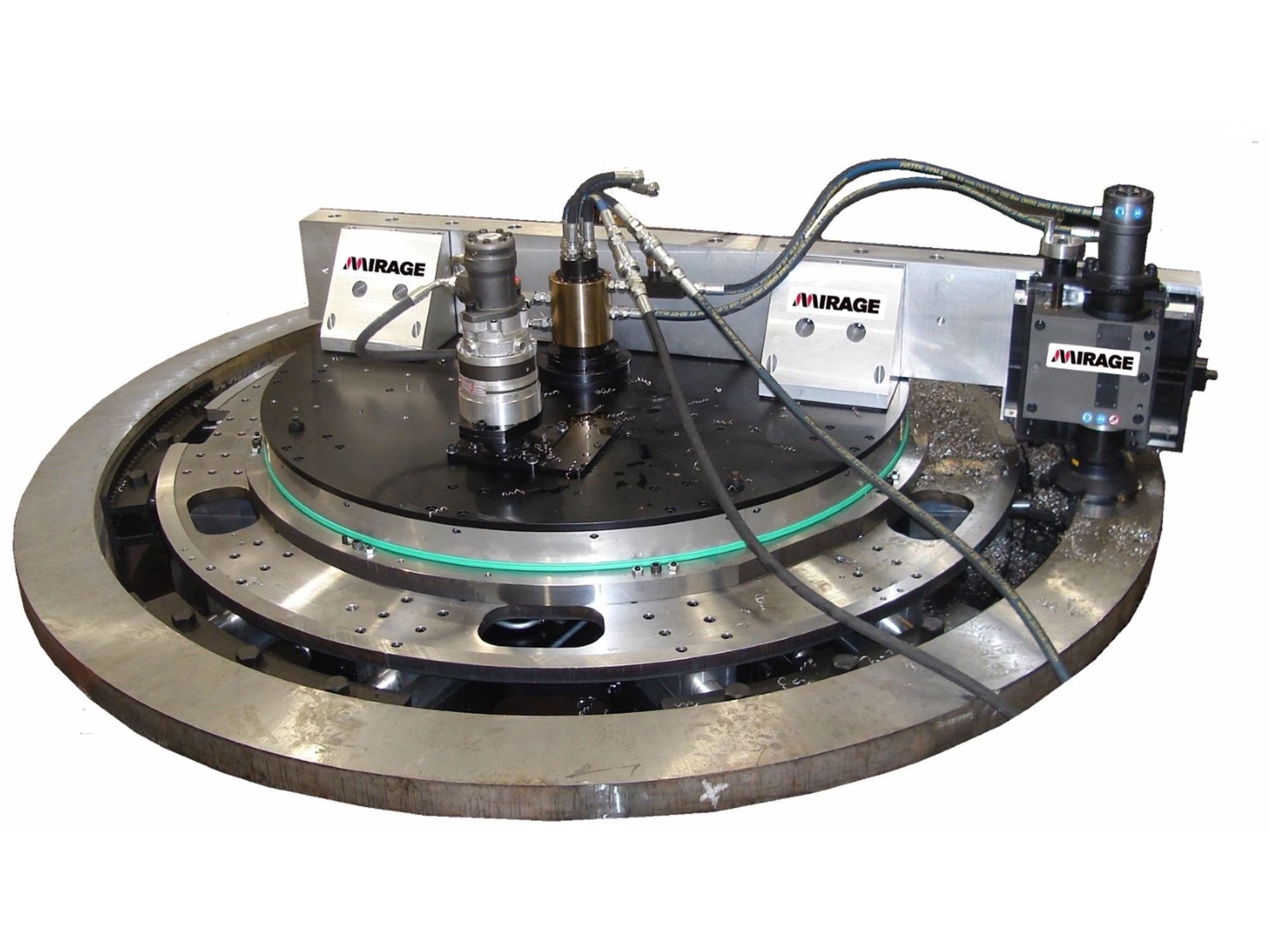

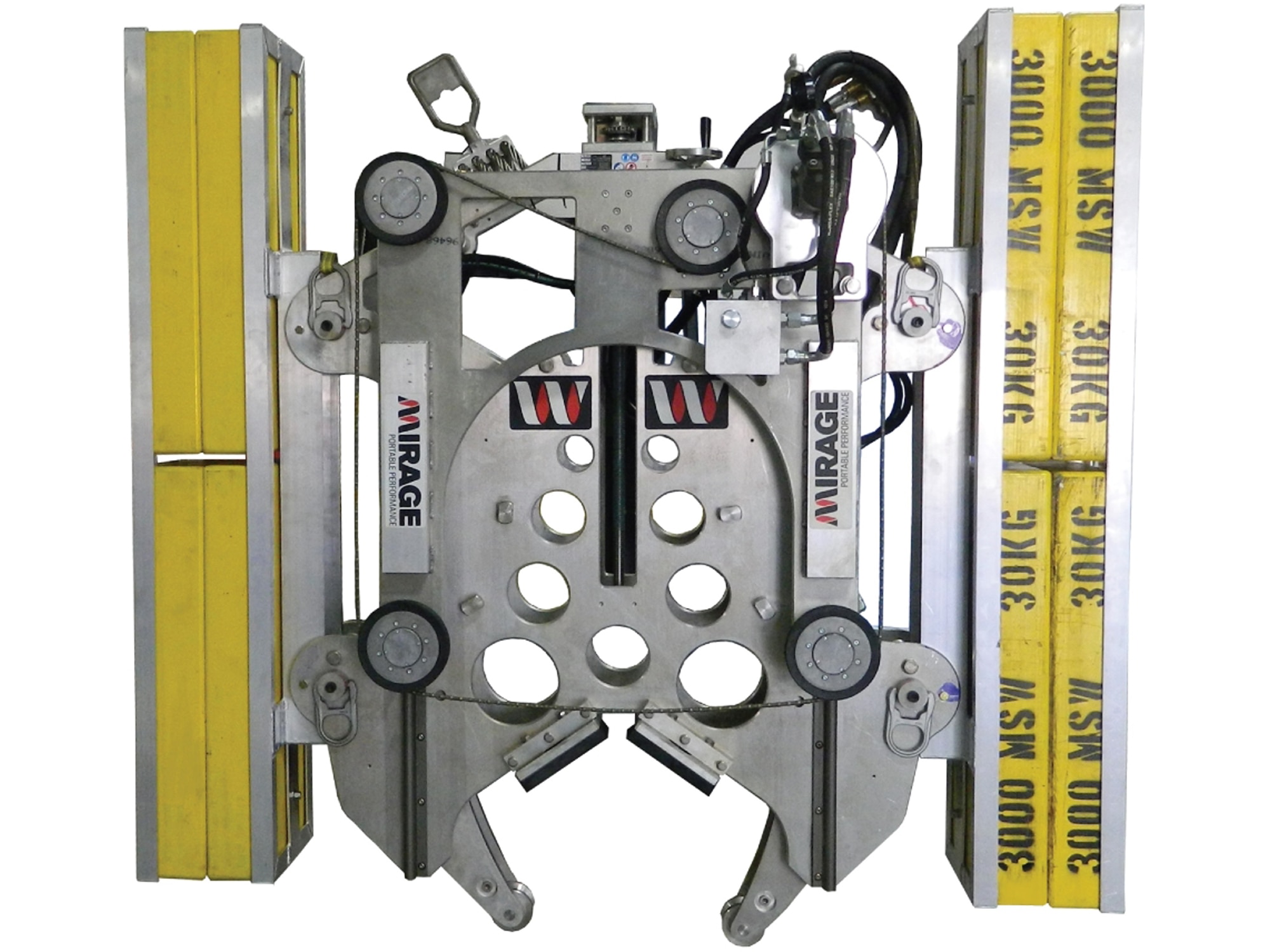

Mirage Portable Machine Tools

Decades of engineering know-how combined with a continuing drive to innovate has resulted in a wide range of world-class portable machining equipment - each machine robust enough to handle the toughest of on-site machining challenges.